What is digital hot stamping technology?

In today's market environment that focuses on visual impact and brand personalization, packaging and printing are no longer just simple functional links, but an important part of brand communication and consumer experience. Among the many post-printing processing technologies, "digital hot stamping technology" as an emerging and efficient process is increasingly being widely adopted in high-end packaging, albums, business cards, invitations and other fields. So, what is digital hot stamping technology? What unique advantages does it have? This article will give you a comprehensive analysis.

Definition of digital hot stamping technology

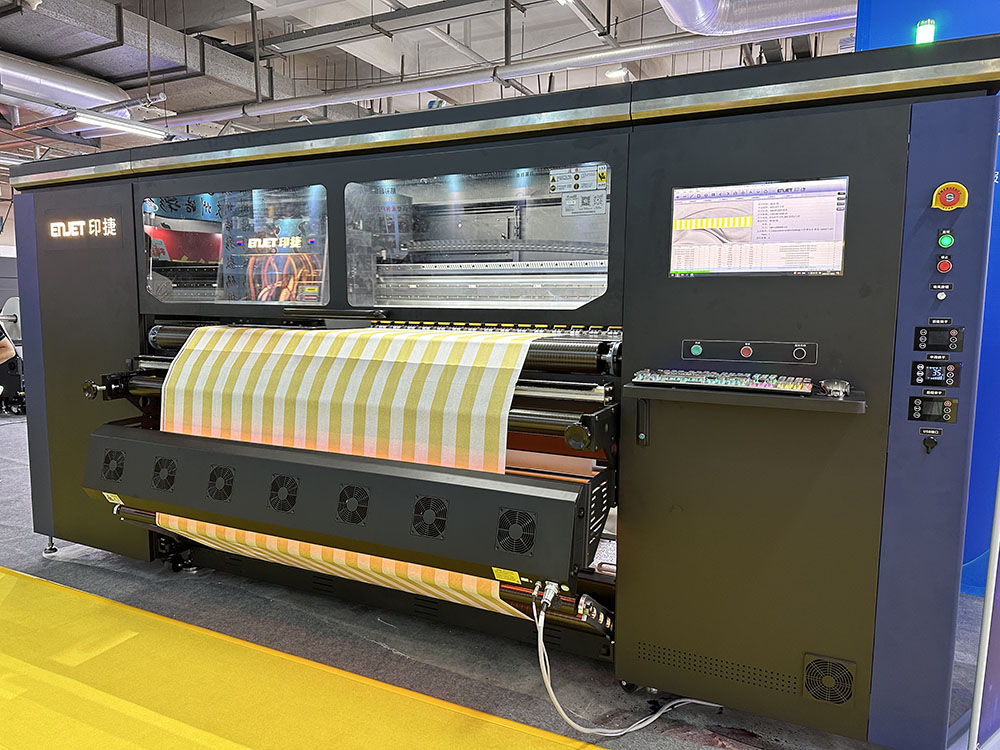

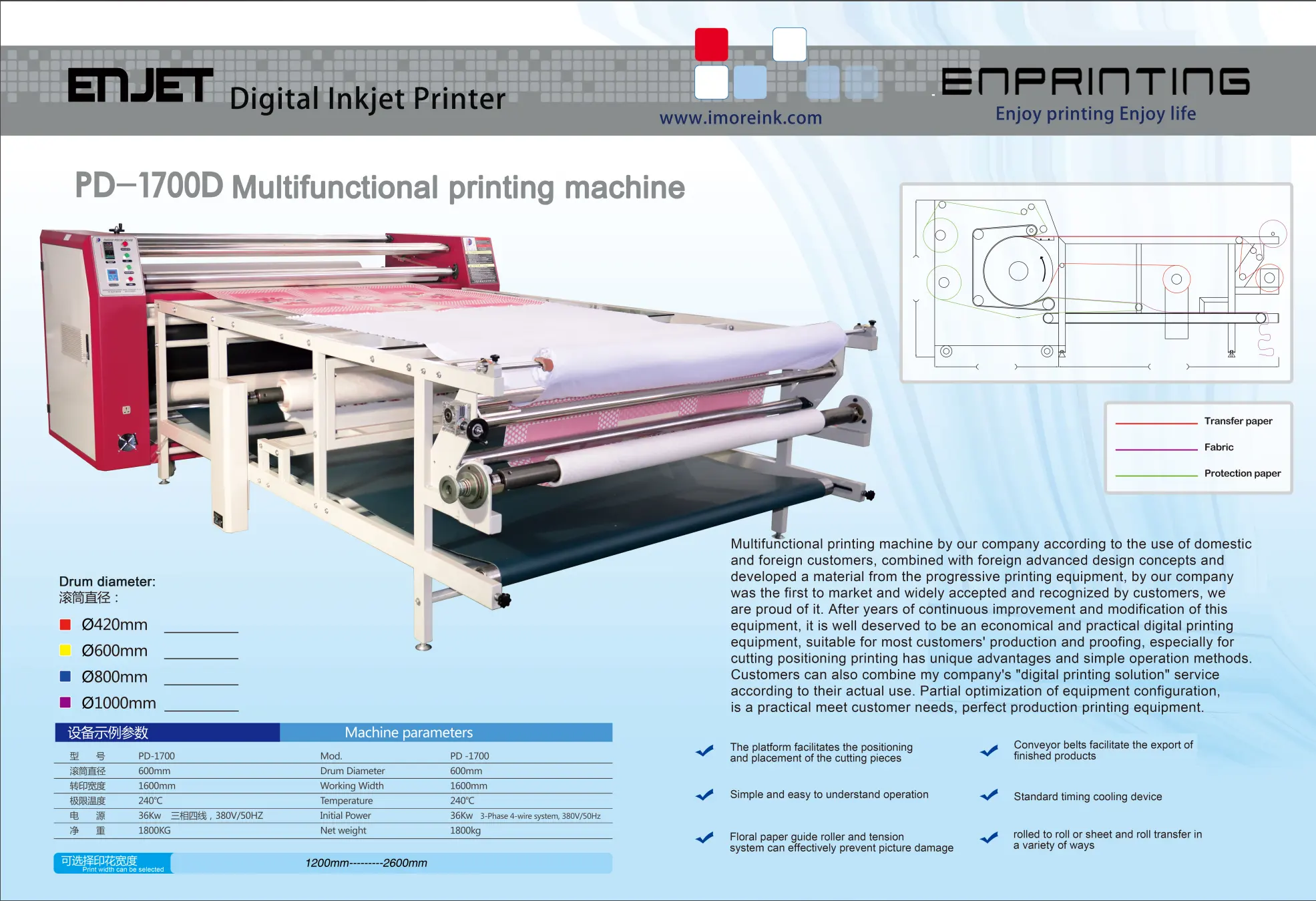

Digital hot stamping, also known as digital foil stamping, is a post-printing process that does not require traditional molds and is performed through digital control. Unlike traditional hot stamping (which requires the production of metal molds), digital hot stamping does not require plate making and can directly complete the transfer of metal texture images on digital prints or specified media.

The basic principle is: use a specific digital hot stamping machine to print a pattern on the surface of the material through a special adhesive, and then use Heat Pressing or UV curing technology to accurately transfer the metal foil (such as gold, silver, and color foil) to the designated pattern area.

The core advantages of digital hot stamping

1. No plate making required, fast delivery

Traditional hot stamping processes often require the production of copper molds or zinc plates, which is time-consuming, labor-intensive and costly. Digital hot stamping uses plateless production, which is suitable for market needs of short-run, personalized, and fast delivery.

2. High precision and flexibility

Digital control makes the positioning of graphics more accurate, even small fonts or complex graphics can be easily achieved. And it can easily cope with a variety of papers and materials, including cardboard, PVC, synthetic paper, etc.

3. Support variable data hot stamping

This is a highlight of digital hot stamping. It supports different patterns and texts for each printed product, such as: name customization, number anti-counterfeiting, QR code hot stamping, etc., which is very suitable for personalized marketing and high-end customized services.

4. Environmentally friendly and efficient

Digital hot stamping reduces the chemical pollution caused by traditional plate making, and can accurately control the use of consumables, reduce waste, and is more in line with the current development trend of green printing.

Applicable scenarios for digital hot stamping

High-end business cards and invitations

Cosmetic packaging boxes, gift boxes

Album covers, book bindings

Labels and anti-counterfeiting logos

Luxury goods, jewelry packaging

Summary

With the increase in personalized printing and green environmental protection needs, digital hot stamping technology is gradually becoming an important development direction for post-printing processing. It not only breaks the limitations of traditional hot stamping, but also gives designers and brand owners greater creative space and market responsiveness.

If you are looking for a fast, exquisite and environmentally friendly metal texture decoration solution, digital hot stamping technology is undoubtedly a choice worth paying attention to and trying.