How do thermal sublimation printers promote the development of the textile industry?

With the continuous advancement of science and technology, the textile industry is undergoing an unprecedented transformation. Especially driven by digital printing technology, traditional production methods are being replaced by more efficient, environmentally friendly and flexible methods. Among them, thermal sublimation printers, as an important representative of digital printing technology, are gradually becoming a key driving force for the development of the textile industry.

What is thermal sublimation printing?

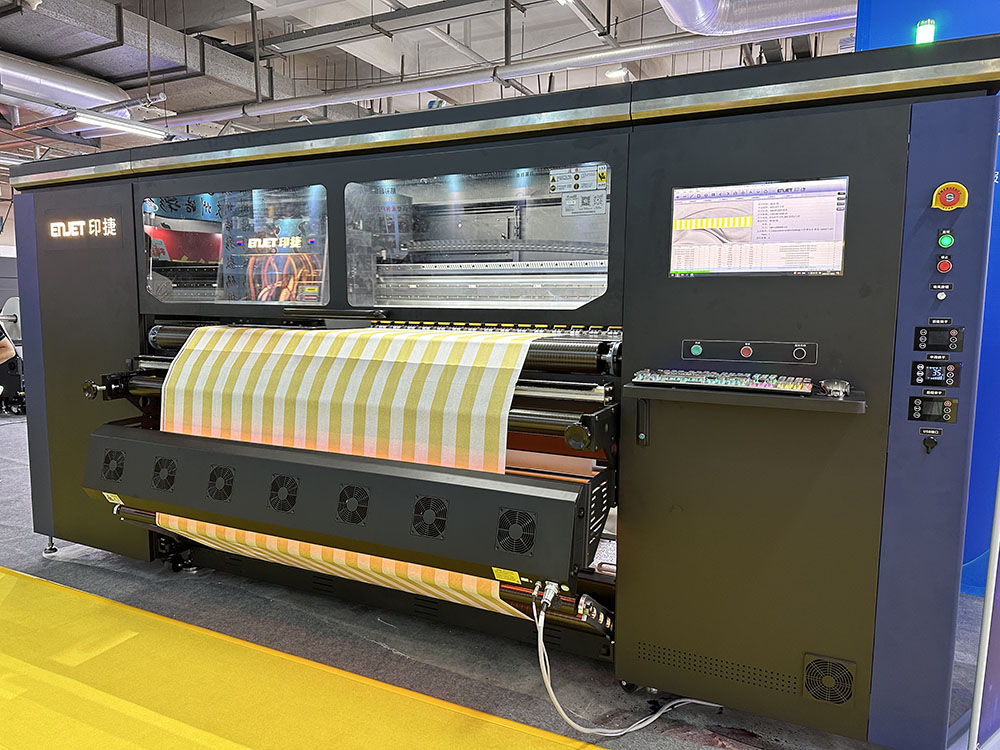

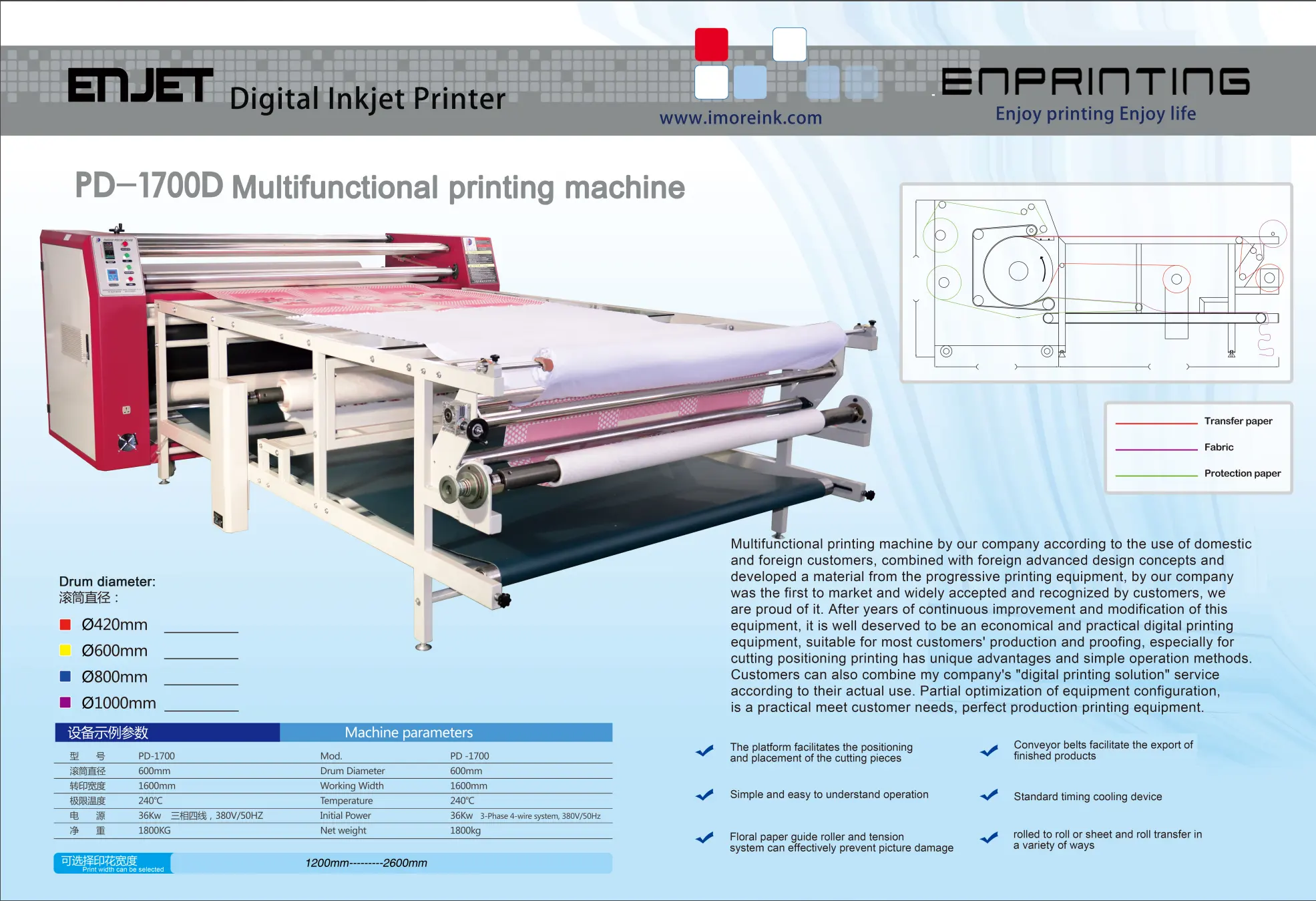

Thermal sublimation printingis a printing technology that uses high temperature to sublimate dyes into fabric fibers. The process usually includes two steps: first, printing on transfer paper with thermal Sublimation Ink, and then transferring the pattern to polyester fabric under high temperature and high pressure. This technology can achieve high-definition and high-color reproduction pattern output, and is widely used in sportswear, home textiles, fashion clothing and other fields.

The positive impact of thermal sublimation printers on the textile industry

1. Improve printing quality

Traditional printing processes are prone to problems such as blurred patterns and large color differences, while thermal sublimation printers have extremely high image reproduction and can present richer and brighter color effects, meeting the market demand for high-end clothing, custom clothing and other high requirements for printing quality.

2. Accelerate production efficiency

Dye-sublimation printing does not require plate making, which eliminates the cumbersome processes in traditional printing and greatly shortens the production cycle. It is especially suitable for small-batch and diversified orders, realizing "printing as soon as the order is received", helping textile companies to quickly respond to market changes and improve delivery efficiency.

3. Green and environmentally friendly

Compared with traditional printing, which uses a lot of water resources and chemical additives, dye-sublimation printing belongs to the "dry transfer" process, which requires almost no water and no wastewater discharge, and conforms to the concept of green production. With increasingly stringent environmental protection policies, environmental protection advantages have become a guarantee for the long-term development of enterprises.

4. Support personalized and customized trends

Modern consumers have an increasing demand for personalized and customized products. Dye-sublimation technology does not require plate making, and the pattern design is flexible. It is very suitable for short-term, small-batch, and multi-style personalized orders, providing more creative space for brands and allowing small and medium-sized enterprises to find a breakthrough in the competition.

5. Expanded application scenarios

Dye-sublimation printing can not only be used for clothing printing, but also widely used in home textile fields such as curtains, bedding, sofa fabrics, cushions, as well as advertising flags, exhibition scenes and other scenes, expanding the product line and market space of textile enterprises.

Development trend of dye-sublimation technology

With the continuous improvement of print head technology, ink stability and color management system, the speed and accuracy of dye-sublimation printers are constantly breaking through. In the future, equipment with integrated automation and intelligent management systems will become the mainstream, further reducing labor costs and improving production efficiency.

At the same time, the emergence of more high-performance fabrics and environmentally friendly inks will also open up new application scenarios for dye-sublimation printing and bring more diverse business opportunities to the textile industry.

Conclusion

Dye-sublimation printers are not only a new type of printing tool, but also an important force for the textile industry to move towards high-quality, green and intelligent manufacturing. Whether from the perspective of improving product competitiveness, responding to market trends, or achieving sustainable development, dye-sublimation technology is becoming a key engine to promote the upgrading of the textile industry.

For textile companies that want to stand out in fierce competition, seizing the opportunities brought by dye-sublimation technology will be an important step in winning the future.